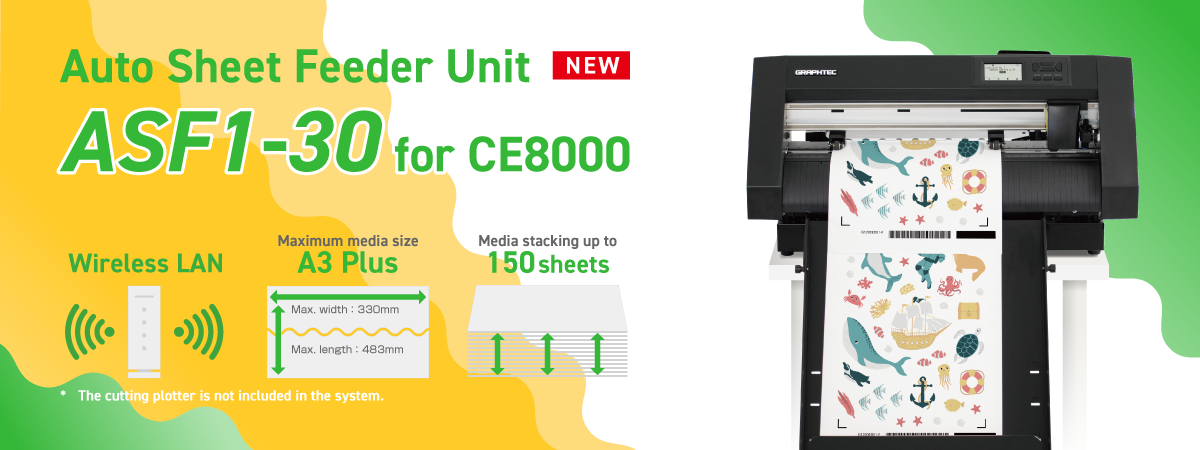

Auto Sheet Feeder Unit ASF1-30 for CE8000

Automation, Labor saving, High efficiency! Best partner to support your cuttings

ASF1-30 is designed to automatically feed and contour cut label media for good price. There are some functions such as barcode function and 2 Registration Marks Alignment which are suitable for various design cutting. Also, the operability has been improved by corresponding to Graphtec original software (Graphtec Studio 2 and Cutting Master 5). It enables to realize reducing lead time, stock and cost.

Best choice for stickers & labels small productions

ASF is suitable for various design in small production of labels, stickers and custom-made merchandises.

Design ⇒ Print ⇒ Set the media… That’s it !

The operation of ASF1-30 is very easy. Just create the design and print it out on tack paper with laser printers, set it to ASF1-30.

How to Create Print & Cut Data

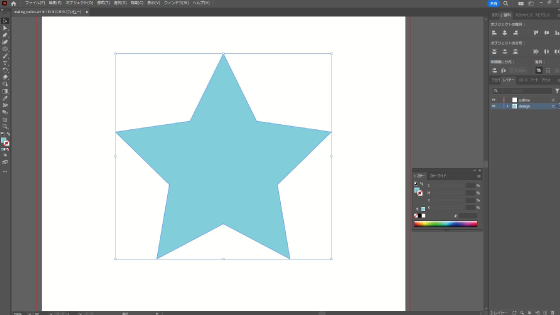

Create a design of labels and stickers in graphic design software (Adobe Illustrator / CorelDRAW / Graphtec Studio 2).

Create cut lines along the contour of the designed object.

Adobe Illustrator display

CE8000-40 and ASF1-30 use Registration Marks to align printing and cutting position.

1. Select the Style of Registration Marks from pull-down menu in Registration Marks panel.

2. Enter line thickness and length of Registration Marks.

3. Click on the check box of [Relative to Page].

4. Enter the distance between the edge of the media and

Registration Marks position and click [OK].

<Tips> Refer to USER’S MANUAL for more details

- Cutting Master 5 USER’S MANUAL <4.1 Basic Workflow for Registration Marks>

- Graphtec Studio 2 USER’S MANUAL <5.1 Basic Workflow for Registration Marks>

Adobe Illustrator display

<Tips> Settings in the video:

- Registration Marks Type: 4 Points Type 2

- Line thickness: 1.0mm

- Length: 20.0mm

- Distance from the edge of the media: left and right sides: 15.0mm / Upper: 37.0mm / Lower: 17.0mm

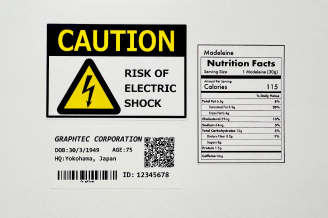

Save labor and improve efficiency with Continuous Cutting Barcode

Data Link Barcode System enables cutting different data sequentially by detecting its linked data from Data Link Server or USB flash memory. It prevents cutting incorrect data and saves labor, increases production efficiency.

This function is available regardless of which printer or RIP software is used.

How to Generate Barcode for Continuous Cutting

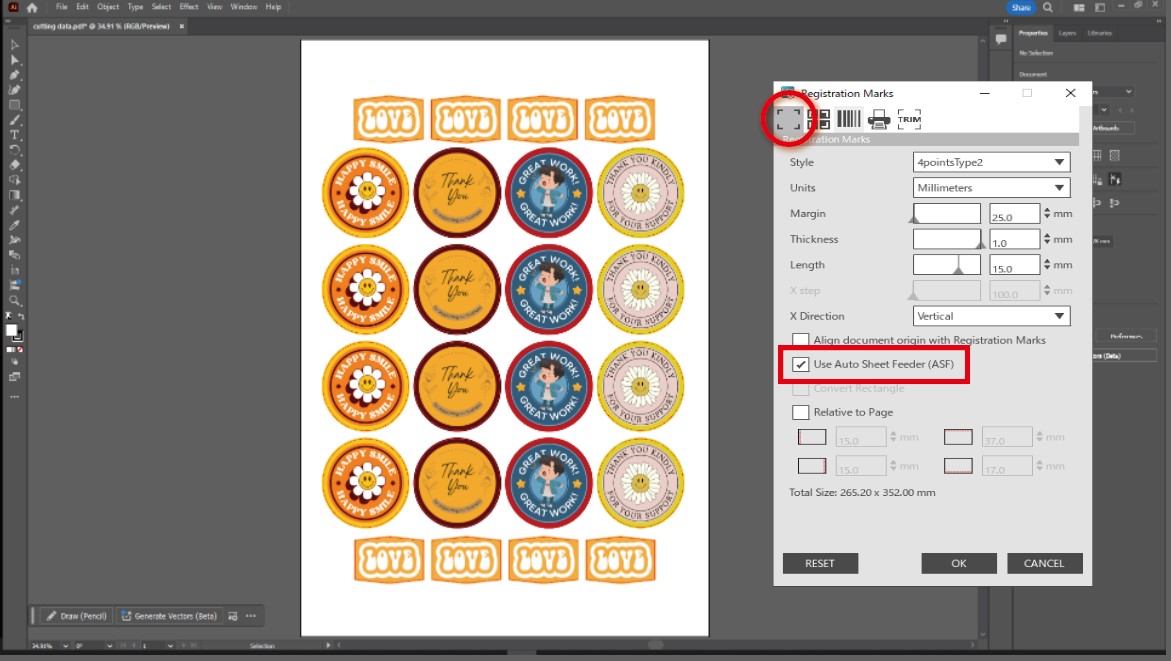

Open the Registration Marks panel in Cutting Master 5 or Graphtec Studio 2 and click on the check box of [Use Auto Sheet Feeder (ASF)].

This can prevent the software from generating Registration Marks or barcodes unavailable with ASF1-30.

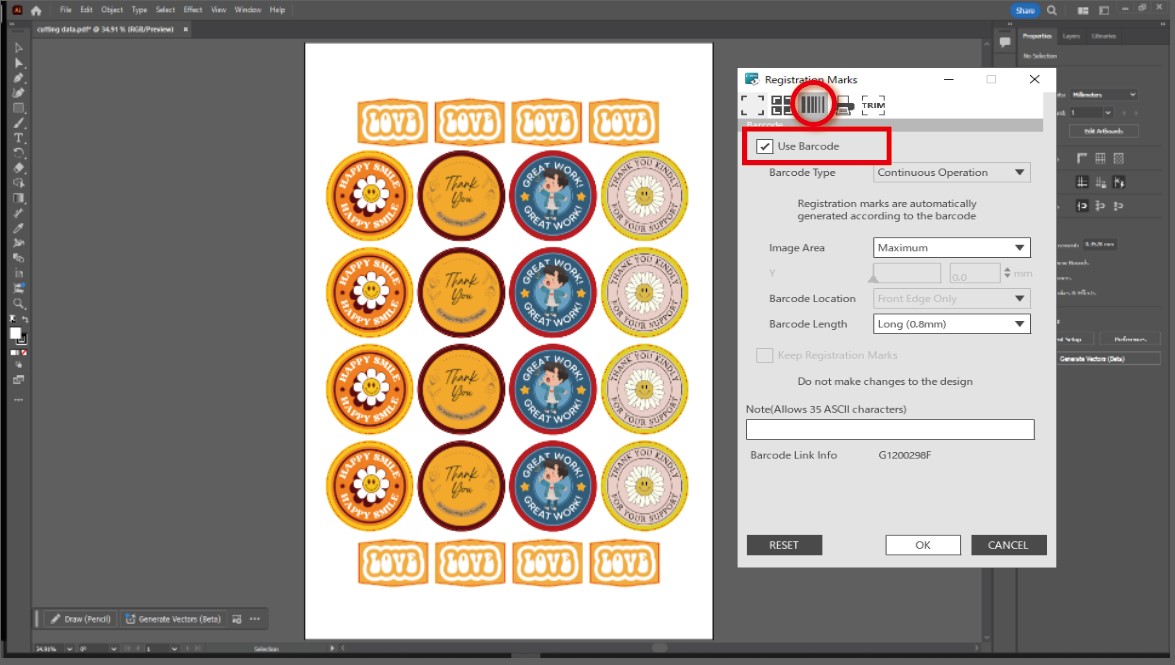

Move on to BARCODE tab and click on the check box of [Use Barcode].

Confirm the values in PRINTER MARGIN tab and click [OK] if there is no problem.

*The margins of the printer driver selected in the application are initialized in PRINTER MARGIN tab.

*When changing the printer, acquire margin information by clicking [Get Printer Margins].

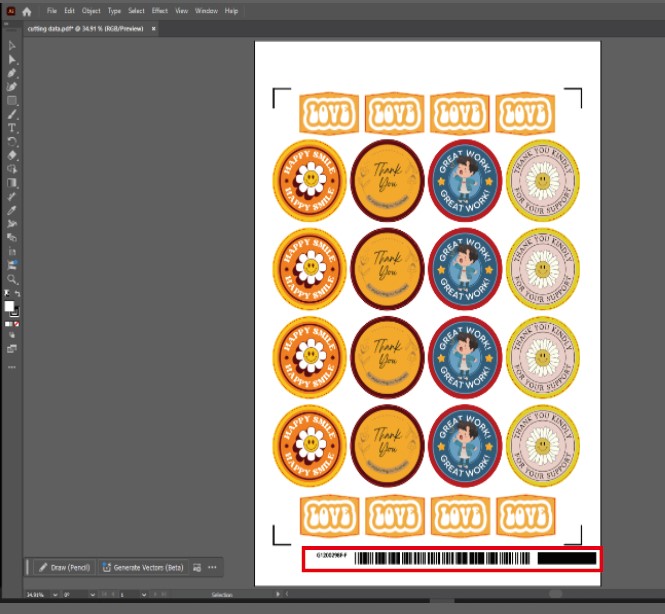

Registration Marks and a barcode are inserted after closing the Registration Marks panel.

High productivity & accuracy guaranteed 2 Registration Marks Alignment

When cutting the same designs multiple times, 2 Registration Marks Alignment can be combined with is the general 4 Registration Marks Alignment.

CE8000-40 reads 4 Registration Marks for the first sheet and only the first 2 for the second sheet and later.

This function helps to reduce operating time while maintaining the high accuracy of cutting.

Other useful functions

office without being limited by the cable length.

of continuous cut will be notified to users by email.

Software

Standard included software for designing your cutting data and operating cutting plotter.

Specifications

ASF1-30 Specifications

| Name | Description |

|---|---|

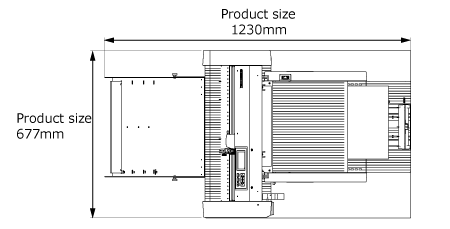

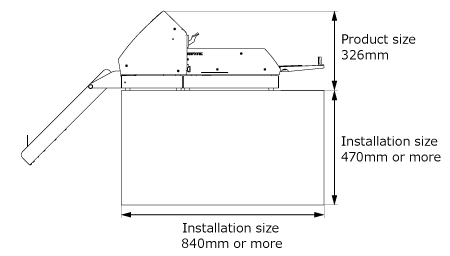

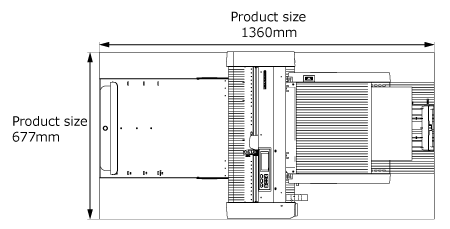

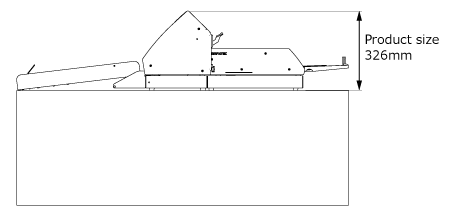

| Dimensions <W×D×H>(Approx.) | 45 degrees angle: 677mm×1230mm×326mm *Table Height 470mm or more Tabletop: 677mm×1360mm×326mm |

| Weight (Approx.) | 24.8kg (Cutter unit 11kg, Auto Feeder unit 7.2kg, Exit tray 6.6kg) |

| Compatible media size | Letter, A4, A3, A3Plus (Vertical setting only) |

| Maximum number of media that can be loaded | 100 Sheets (Thick paper) – 150 Sheets (Thin paper) |

| Compatible media | Tack paper (for laser printer) Thickness 0.15 to 0.23 mm (157 to 181 g/m2) Basis weight is for reference only Static electricity generating media and copy paper, etc. are not available. |

| Operating environment | 15ºC to 35ºC, 70% R.H. (non-condensing) |

| Curl Tolerance | 5mm or less |

Auto Sheet Feeder Unit (ASF1-30) Standard accessories

Accessories contained with ASF1-30

- Connection cable

- Cable cover

- Extension tray

Accessories contained in the packaging box of the media output tray

- CE8000 base

- ASF1-30 base

- Base connecting parts (2 pcs)

- Media output tray

- Media Stopper

- Tray fixing bracket A / B (1 pc of each)

- Screws A (3 pcs)

- Screws B (12 pcs)

- Setup manual / Request for firmware and software updates

Dimensions

<45-degree use>

<Tabletop use>

- Tolerance: ±5 mm

- Frontward and backward the machine, please take enough space for operation.

- The installation size (area) when installing on a tabletop should be larger size than the product size.

- There is no specific recommended value for the height when installing on a tabletop.